|

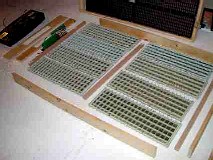

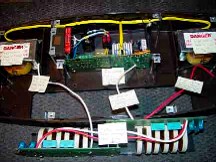

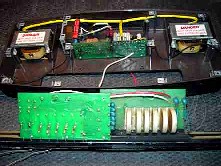

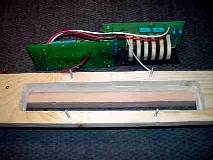

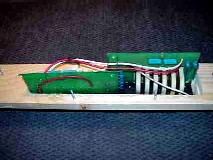

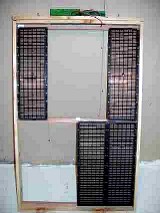

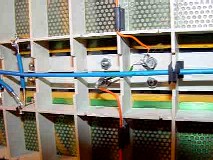

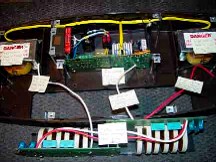

In this image, labels on the various wires show how the delay line and other components in the plinth of an ESL-63 interconnect. To separate the plinth from the panel assembly, turn the speaker upside down, and unscrew the baseplate from the bottom of the plinth. Despite all the electronics in the plinth, there are only four wires which connect the plinth to the panel assembly, and they are simple to remove and replace. The first wire is the coiled orange wire in the exact centre of the plinth. It exits the rectifier, and feeds high-voltage to the speaker's diaphragms via a hole drilled in the extruded metal base of the panel assembly. Cut this wire where it is soldered to the rectifier board. The second and third wires feed amplifier output to the delay line, via one wire from each of the two high-voltage step-up transformers. Cut both wires where they are soldered to the tranformers and remove the rubber plugs which hold them in place as they run from the transformers to the delay line. Wires connecting components in the plinth to the delay line have to be cut because the delay line is not attached to the plinth, but to the extruded metal base of the panel assembly. The fourth wire is the protection circuit's 'sniffer' wire. This is the white wire on the top of the delay line board. You cannot mistake this wire because it hangs loose at one end, ending in thin air. Because this wire is on top of, at right angles to, and in contact with, the high-voltage output wires, they generate sympathetic 'eddy currents' in it. If these eddies exceed a pre-set level, they signify to the protection circuitry that arcing may occur, and the amplifier input is immediately short-circuited. This sniffer wire feeds through two guide holes in the delay line assembly. Because it is free at one end, nothing needs to be cut or disconnected. The wire is simply pulled out of the guide holes. Replace it exactly as it was when re-assembling the speaker, or else the protection circuit will not function. Once these wires are disconnected, locate and unscrew the eight bolts holding the plinth to the panel assembly. The bolt-hole protrusions for four of the bolts are visible in this image. The following image shows the other four. Once all bolts are unscrewed, lift the plinth off the panel assembly. Follow the above procedures in reverse order to re-assemble the speaker.

|