Quad ESL-63 repair by Hey You

click on any pic to download a ~2MB huge a hi-rez photo

Quad ESL-63 repair by Hey You

click on any pic to download a ~2MB huge a hi-rez photo

|

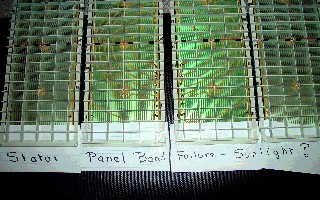

This image shows the four panels as they would have been in the speaker. I have slipped sheets of paper between the stator and the grid to show where the bond has failed.

|

|

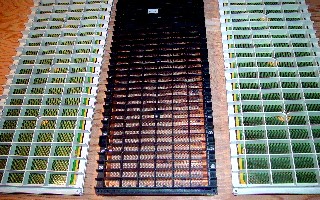

This image shows an early Quad panel alongside the later USA Monitor panels. The USA Monitor panel is actually less rigid (but acoustically more open) than the panel it supplanted.

|

|

|

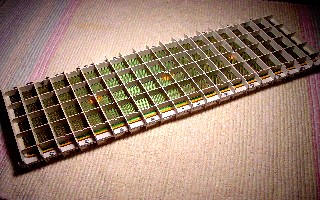

In this image, the front panel is bonded to the diaphragm.

|

|

|

This image shows a rebuilt panel with reinforcing bolts installed around the perimeter.

|

|

|

This image shows two reassembled panels receiving a 24 hour test prior to being returned to the client.

|

|