|

This image shows the two top segments of the ESL-63 after removal, exposing the panel assembly for removal.

|

|

|

This image shows the entire panel assembly completely removed from the speaker frame.

|

|

|

This image shows the empty speaker frame after the panel assembly has been removed.

|

|

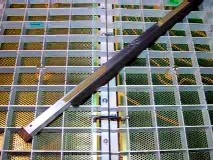

This image shows the extruded metal panel assembly frame laid on top of the panels. Note the liberal use of foam rubber.

|

|

This image shows the speaker with the panel assembly reinstalled and soldered, ready to have the dustcover film attached.

|

|

|

This image shows the electronics in the plinth of a "Crosby Mod" ESL-63.

|

|

|

This image shows the "certificate" of modification, written on the inside of the baseplate of the plinth.

|

|

This image shows a very elegant Crosby ESL-63 with all four of its panels rebuilt. The beautiful open honeycomb grill and sheer nylon sock reveal the speaker interior.

|

|